Page 65 - 건축구조 Vol. 29 / No. 03

P. 65

Project focus Compton and Edrich stands, Lord’s Cricket Ground Compton and Edrich stands, Lord’s Cricket Ground Project focus

Compton and Edrich stands, Lord’s Cricket Ground Project focus

Compton and Edrich stands, Lord’s Cricket Ground Project focus

Compton and Edrich stands, Lord’s Cricket Ground Project focus

Design and construction of the Compton and Edrich stands, Lord’s Cricket Ground redevelopment

the rakers onto which the canopy rib would

creating a common, clean aesthetic throughout the rakers onto which the canopy rib would

the rakers onto which the canopy rib would

connect. This survey information was fed into

the stands. connect. This survey information was fed into

connect. This survey information was fed into

the Tekla model to enable any deviations from

An added benefit of the chosen solution the rakers onto which the canopy rib would

the Tekla model to enable any deviations from

the Tekla model to enable any deviations from

theoretical to be incorporated at the detailing

compared with others considered was the theoretical to be incorporated at the detailing

connect. This survey information was fed into

theoretical to be incorporated at the detailing

stage, thus minimising potential inaccuracies

minimum fabrication content, to the benefit of the Tekla model to enable any deviations from

stage, thus minimising potential inaccuracies

stage, thus minimising potential inaccuracies

during installation. Overall, the canopy fitted

the project overall. during installation. Overall, the canopy fitted

during installation. Overall, the canopy fitted

theoretical to be incorporated at the detailing

together exceptionally well given the complex

The construction logistics of the site were together exceptionally well given the complex

together exceptionally well given the complex

stage, thus minimising potential inaccuracies

geometry, with tip locations generally being

particularly challenging, with only a single during installation. Overall, the canopy fitted

geometry, with tip locations generally being

geometry, with tip locations generally being

within 25mm of theoretical.

access point for vehicles that involved driving together exceptionally well given the complex

within 25mm of theoretical.

within 25mm of theoretical.

through areas that were open to the public, geometry, with tip locations generally being

as the Indoor Cricket Centre needed to Conclusion

within 25mm of theoretical.

Lord’s Cricket Ground required stands of

Conclusion

Conclusion

remain in use throughout the majority of the Lord’s Cricket Ground required stands of

Lor

ound r

s Cricket Gr

d’

equir

ed stands of

significant merit that would integrate with the

construction works. To complicate matters, the significant merit that would integrate with the

significant merit that would integrate with the

Ground’s character. The team worked to deliver

Conclusion

single access point needed to feed four work Gr ound’ s character . The team worked to deliver

Lord’s Cricket Ground required stands of

Ground’s character. The team worked to deliver

the complex engineering solutions required

fronts for both steelwork and precast concrete the complex engineering solutions required

equir

significant merit that would integrate with the

ed

the complex engineering solutions r

for this high-quality project, and to overcome

deliveries. FIGURE 14: 3D model Ground’s character. The team worked to deliver

oject, and to over

for this high-quality project, and to overcome

for this high-quality pr

come

construction problems associated with this

To construct the stands, Severfield primarily

construction pr

oblems associated with this

the complex engineering solutions required

construction problems associated with this

unique site. Complex projects of this nature,

unique site. Complex projects of this nature,

for this high-quality project, and to overcome

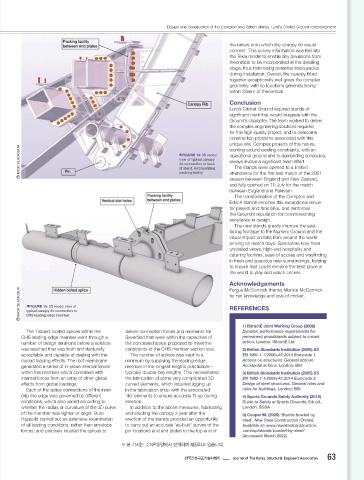

3D model

FIGURE 14: 3D model

working around existing constraints, with an

FIGURE 14:

– allowing both stands to be constructed at

rib connection to back

view of typical canopy

FIGURE 11: 3D MICK SLACK/SUK used four mobile cranes working concurrently MICK SLACK/SUK MICK SLACK/SUK MICK SLACK/SUK view of typical canopy unique site. Complex projects of this nature,

view of typical canopy

working ar

ound existing constraints, with an

working around existing constraints, with an

construction problems associated with this

operational ground and to demanding schedules,

rib connection to back

rib connection to back

model view of adopted the same time. (For further details, see article of stand, incorporating

operational ground and to demanding schedules,

operational gr

ound and to demanding schedules,

always involve a significant team effort.

packing facility

of stand, incorporating

of stand, incorporating

detail for typical raker– in NSC .) FIGURE 14: 3D model unique site. Complex projects of this nature,

5

always involve a significant team effort.

always involve a significant team effort.

column connection MICK SLACK/SUK view of typical canopy working around existing constraints, with an

The stands were opened to a limited

packing facility

packing facility

The longest upper-tier rakers were up to rib connection to back operational ground and to demanding schedules,

The stands wer

e opened to a limited

The stands were opened to a limited

attendance for the first test match of the 2021

20m long. This is marginally over a commonly of stand, incorporating attendance for the first test match of the 2021

always involve a significant team effort.

attendance for the first test match of the 2021

packing facility

season between England and New Zealand,

accepted transport limit of 18m, but Severfield season between England and New Zealand,

season between England and New Zealand,

The stands were opened to a limited

and fully opened on 10 July for the match

transfer between rakers/columns. FIGURE 12: MEP installation, with pre-detailed service established that it would be beneficial to and fully opened on 10 July for the match

and fully opened on 10 July for the match

attendance for the first test match of the 2021

between England and Pakistan.

The detail was developed collaboratively holes in steelwork fabricate and transport these as single-raker season between England and New Zealand,

between England and Pakistan.

between England and Pakistan.

The transformation of the Compton and

between all parties; it involved widening the units rather than include site splices. The and fully opened on 10 July for the match

The transformation of the Compton and

The transformation of the Compton and

Edrich stands enriches this exceptional venue

top/bottom flanges of the raker local to the weights were up to 22t, requiring an additional between England and Pakistan.

Edrich stands enriches this exceptional venue

Edrich stands enriches this exceptional venue

for players and fans alike, and reinforces

column, enabling the upper and lower column 300t capacity crane. During March 2020 there for players and fans alike, and r einfor ces

for players and fans alike, and reinforces

The transformation of the Compton and

the Ground’s reputation for commissioning

assemblies to bolt directly to the raker section was a fifth crane on site – a self-erecting tower the Ground’s reputation for commissioning

Edrich stands enriches this exceptional venue

s r

the Gr

eputation for commissioning

ound’

excellence in design.

(Figure 11). The increased flange width was crane – installing the steel stairs. excellence in design.

for players and fans alike, and reinforces

excellence in design.

The new stands greatly improve the east-

achieved by locally inserting a wider, ‘thicker’ the Ground’s reputation for commissioning

eatly impr

ove the east-

The new stands greatly improve the east-

The new stands gr

facing frontage to the Nursery Ground and the

flange plate – facilitated by virtue of the raker June 2020 onwards: roof fabrication and excellence in design. ound and the

facing fr

facing frontage to the Nursery Ground and the

ontage to the Nursery Gr

visual impact on fans from around the world

sections being ‘fabricated’ plate girders, giving erection visual impact on fans from around the world

om ar

The new stands greatly improve the east-

visual impact on fans fr

ound the world

arriving on match days. Spectators now have

greater flexibility for local thickening of material Building works continued through what had facing frontage to the Nursery Ground and the

arriving on match days. Spectators now have

arriving on match days. Spectators now have

unrivalled views, high-end hospitality and

where required. been anticipated to be the 2020 summer unrivalled views, high-end hospitality and

unrivalled views, high-end hospitality and

visual impact on fans from around the world

catering facilities, ease of access and wayfinding

The widened flange plates were specified cricket season and into the next closed season arriving on match days. Spectators now have

catering facilities, ease of access and wayfinding

catering facilities, ease of access and wayfinding

in fresh and spacious new surroundings, helping

to be slightly thicker than required, enabling from September. The phases after the main unrivalled views, high-end hospitality and

in fr

in fresh and spacious new surroundings, helping

esh and spacious new surr

oundings, helping

to ensure that Lord’s remains the best place in

the plates to be machined flat after completion frame erection included blockwork installation, to ensur e that Lor d’ s r emains the best place in

catering facilities, ease of access and wayfinding

to ensure that Lord’s remains the best place in

the world to play and watch cricket.

of all welding (thus accounting for potential dry lining and MEP fit-out (Figure 12). The in fresh and spacious new surroundings, helping

the world to play and watch cricket.

the world to play and watch cricket.

‘distortions’ due to welding processes), to final construction phases included bar and to ensure that Lord’s remains the best place in

provide a suitable bearing fit-up between the restaurant fit-out, and the erection of the Acknowledgements

the world to play and watch cricket.

Fergus McCormick thanks Monica McCormick

Acknowledgements

Acknowledgements

rakers and columns. FERGUS McCORMICK/BURO HAPPOLD stands’ steel-framed roofs and the steel link Fergus McCormick thanks Monica McCormick

Fergus McCormick thanks Monica McCormick

for her knowledge and love of cricket.

The column section was effectively replicated bridge. for her knowledge and love of cricket.

for her knowledge and love of cricket.

within the depth of the raker, ensuring a direct The first major challenge in developing the MICK SLACK/SUK FIGURE 15: 3D model view of Acknowledgements

Fergus McCormick thanks Monica McCormick

load path with minimal internal stiffening. steelwork connection details for the canopy MICK SLACK/SUK MICK SLACK/SUK typical canopy rib connection to REFERENCES

3D model view of

FIGURE 15: 3D model view of

for her knowledge and love of cricket.

FIGURE 15:

REFERENCES

The principles of this detail were adopted as was to ensure accurate location of the roof CHS leading-edge member REFERENCES

typical canopy rib connection to

typical canopy rib connection to

CHS leading-edge member

standard at levels 2, 3 and 4 on all primary cantilever tip, in elevation and on plan. This MICK SLACK/SUK CHS leading-edge member

FIGURE 15: 3D model view of

1) IStructE Joint Working Group (2008)

frame gridlines, maximising rationalisation, and was required both for the structural fit-up of the typical canopy rib connection to REFERENCES

Dynamic performance requirements for

1) IStructE Joint W

orking Gr

oup (2008)

CHS leading-edge members with the cantilever CHS leading-edge member deliver connection forces and moments for 1) IStructE Joint Working Group (2008)

The ‘hidden’ bolted splices within the

Dynamic performance requirements for

Dynamic performance requirements for

tip and for ensuring a smooth, continuous CHS leading-edge member went through a deliver connection forces and moments for permanent grandstands subject to crowd

ces and moments for

deliver connection for

The ‘hidden’ bolted splices within the

The ‘hidden’ bolted splices within the

Severfield that were within the capacities of

action, London: IStructE Ltd

permanent grandstands subject to crowd

permanent grandstands subject to crowd

1) IStructE Joint Working Group (2008)

FIGURE 13: View from curve and smooth aesthetic to the members CHS leading-edge member went thr ough a Severfield that were within the capacities of action, London: IStructE Ltd

e within the capacities of

CHS leading-edge member went through a

Severfield that wer

, London: IStructE Ltd

number of design iterations before a solution

the concealed splice proposed to meet the

action

Dynamic performance requirements for

upper tier of Edrich stand (Figure 13). number of design iterations before a solution the concealed splice pr oposed to meet the 2) British Standards Institution (2006) BS

e a solution

The ‘hidden’ bolted splices within the

the concealed splice proposed to meet the

deliver connection forces and moments for

number of design iterations befor

was reached that was both architecturally

constraints of the CHS member section size.

looking north across rear The challenge was addressed by designing permanent grandstands subject to crowd

2) British Standards Institution (2006) BS

ds Institution (2006)

EN 1991-1-7:2006+A1:2014 Eurocode 1.

2) British Standar

BS

eached that was both ar

was reached that was both architecturally

constraints of the CHS member section size.

chitecturally

constraints of the CHS member section size.

was r

acceptable and capable of dealing with the

The number of splices was kept to a

of Media Centre towards CHS leading-edge member went through a Severfield that were within the capacities of action, London: IStructE Ltd

EN 1991-1-7:2006+A1:2014 Eurocode 1.

EN 1991-1-7:2006+A1:2014 Eurocode 1.

Actions on structures. General actions.

acceptable and capable of dealing with the

canopy of Compton and incorporating sufficient scope for acceptable and capable of dealing with the the concealed splice proposed to meet the Accidental actions, London: BSI

The number of splices was kept to a

number of design iterations before a solution

The number of splices was kept to a

myriad loading effects. The roof membrane

minimum by supplying the leading-edge

Actions on structures. General actions.

Actions on structures. General actions.

stand adjustment to accommodate potential building myriad loading effects. The r oof membrane minimum by supplying the leading-edge 2) British Standards Institution (2006) BS

Accidental actions, London: BSI

was reached that was both architecturally

constraints of the CHS member section size.

minimum by supplying the leading-edge

myriad loading effects. The roof membrane

London: BSI

member in the longest lengths practicable –

generated a series of in-plane internal forces

Accidental actions,

3) British Standards Institution (2005) BS

tolerances. Several measures were adopted, generated a series of in-plane internal forces member in the longest lengths practicable – EN 1991-1-7:2006+A1:2014 Eurocode 1.

The number of splices was kept to a

ces

generated a series of in-plane inter

nal for

acceptable and capable of dealing with the

member in the longest lengths practicable –

within this member which combined with

typically double-bay lengths. This necessitated

Actions on structures. General actions.

BS

ds Institution (2005)

3) British Standar

3) British Standards Institution (2005) BS

including a packing facility incorporated within within this member which combined with minimum by supplying the leading-edge EN 1993-1-1:2005+A1:2014 Eurocode 3.

typically double-bay lengths. This necessitated

myriad loading effects. The roof membrane

Accidental actions, London: BSI

within this member which combined with

typically double-bay lengths. This necessitated

internal forces from an array of other global

the fabrication of some very complicated 3D

Design of steel structures. General rules and

EN 1993-1-1:2005+A1:2014 Eurocode 3.

EN 1993-1-1:2005+A1:2014 Eurocode 3.

each connection of the canopy rib to the back

STEVE MACEY/BURO HAPPOLD required careful coordination to achieve the internal forces from an array of other global in the fabrication shop with the associated 4) Sports Grounds Safety Authority (2018)

ces fr

nal for

om an array of other global

inter

generated a series of in-plane internal forces

internal forces from an array of other global

member in the longest lengths practicable –

the fabrication of some very complicated 3D

the fabrication of some very complicated 3D

rules for buildings, London: BSI

effects from global loadings.

curved elements, which required jigging up

Design of steel structures. General rules and

Design of steel structures. General rules and

3) British Standards Institution (2005) BS

of the stand. This detail is highly visible and

equir

London: BSI

om global loadings.

rules for buildings, London: BSI

curved elements, which r

effects fr

typically double-bay lengths. This necessitated

curved elements, which required jigging up

effects from global loadings.

ed jigging up

within this member which combined with

Each of the splice connections of the inner

in the fabrication shop with the associated

rules for buildings,

EN 1993-1-1:2005+A1:2014 Eurocode 3.

the fabrication of some very complicated 3D

in the fabrication shop with the associated

Each of the splice connections of the inner

Each of the splice connections of the inner

drip line edge was governed by different

‘rib’ elements to ensure accurate fit-up during

Guide to Safety at Sports Grounds, 6th ed.,

4) Sports Grounds Safety Authority (2018)

4) Sports Grounds Safety Authority (2018)

Design of steel structures. General rules and

desired architectural intent while dealing with

drip line edge was governed by different

ent

drip line edge was gover

effects from global loadings.

e accurate fit-up during

‘rib’ elements to ensure accurate fit-up during

‘rib’ elements to ensur

curved elements, which required jigging up

ned by differ

rules for buildings, London: BSI

conditions, which also varied according to

erection.

, 6th ed.,

London: SGSA

Guide to Safety at Sports Grounds, 6th ed.,

Guide to Safety at Sports Grounds

significant multi-planar forces and varying 3D

er

in the fabrication shop with the associated

Each of the splice connections of the inner

ding to

conditions, which also varied accor

ection.

erection.

conditions, which also varied according to

London: SGSA

In addition to the above measures, fabricating

London: SGSA

whether the radius or curvature of the 3D curve

4) Sports Grounds Safety Authority (2018)

5) Cooper M. (2020) ‘Stands bowled by

geometry around the stands (Figure 14).

whether the radius or curvatur

drip line edge was governed by different

In addition to the above measur

whether the radius or curvature of the 3D curve

e of the 3D curve

‘rib’ elements to ensure accurate fit-up during

es, fabricating

In addition to the above measures, fabricating

and erecting the canopy a year after the

of the member was tighter or larger. Buro

Guide to Safety at Sports Grounds, 6th ed.,

Stands bowled by

5) Cooper M. (2020) ‘Stands bowled by

steel’, New Steel Construction [Online]

The connection of the canopy rib to the CHS

5) Cooper M. (2020) ‘

of the member was tighter or larger

and erecting the canopy a year after the

and er

of the member was tighter or larger. Buro

erection.

ecting the canopy a year after the

o

conditions, which also varied according to

. Bur

London: SGSA

erection of the stands provided an opportunity

Happold carried out an extensive examination

steel’,

steel’, New Steel Construction [Online]

[Online]

Available at: www.newsteelconstruction.

New Steel Construction

leading-edge member incorporated slot holes

ection of the stands pr

ovided an opportunity

In addition to the above measures, fabricating

er

Happold carried out an extensive examination

whether the radius or curvature of the 3D curve

of all loading conditions, rather than envelope

to carry out an accurate ‘as-built’ survey of the

Available at: www.newsteelconstruction.

vailable at: www

.newsteelconstruction.

A

5) Cooper M. (2020) ‘Stands bowled by

for vertical adjustment as well as a facility for

to carry out an accurate ‘as-built’ survey of the

of the member was tighter or larger. Buro

of all loading conditions, rather than envelope

and erecting the canopy a year after the

of all loading conditions, rather than envelope

to carry out an accurate ‘as-built’ survey of the

forces, and precisely located the splices to

pin locations and end plates to the top end of

(Accessed: March 2022)

com/wp/stands-bowled-by-steel/

com/wp/stands-bowled-by-steel/

steel’, New Steel Construction [Online]

erection of the stands provided an opportunity

ecisely located the splices to

pin locations and end plates to the top end of

pin locations and end plates to the top end of

ces, and pr

for

forces, and precisely located the splices to

Happold carried out an extensive examination

(Accessed: March 2022)

ch 2022)

packing to aid alignment on plan (Figure 15). Happold carried out an extensive examination erection of the stands provided an opportunity com/wp/stands-bowled-by-steel/

(Accessed: Mar

Available at: www.newsteelconstruction.

of all loading conditions, rather than envelope to carry out an accurate ‘as-built’ survey of the com/wp/stands-bowled-by-steel/

32

32 forces, and precisely located the splices to ※ 본 기사는 CNP동양에서 선택하여 제공하고 있습니다. (Accessed: March 2022)

33

pin locations and end plates to the top end of

33

32

32

32

32

32

32

33

33

.org

May 2022 | thestructuralengineer

May 2022 | thestructuralengineer.org thestructuralengineer.org | May 2022

May 2022 | thestructuralengineer.org

May 2022 | thestructuralengineer .org thestructuralengineer.org | May 2022 Journal of The Korea Structural Engineers Association 63

May 2022 | thestructuralengineer

.org | May 2022

May 2022 | thestructuralengineer.org

May 2022 | thestructuralengineer

May 2022 | thestructuralengineer

thestructuralengineer

.org

thestructuralengineer.org | May 2022

.org

.org

한국건축구조기술사회지

32

32 33

.org

May 2022 | thestructuralengineer

May 2022 | thestructuralengineer.org Lords Cricket St_TSE May 2022_The Structural Engineer.indd 33 thestructuralengineer.org | May 2022 20/04/2022 09:50

Lords Cricket St_TSE May 2022_The Structural Engineer.indd 32 20/04/2022 09:50

20/04/2022 09:50

Lords Cricket St_TSE May 2022_The Structural Engineer.indd 33 20/04/2022 09:50

Lords Cricket St_TSE May 2022_The Structural Engineer.indd 33

Lords Cricket St_TSE May 2022_The Structural Engineer.indd 33 20/04/2022 09:50